1 Environmental Monitoring

Cleanroom Solutions provide a fully integrated Environmental Monitoring System that can also be 21CFR Part 11 compliant.

With a range of high-performance multifunction sensors, temperature, humidity, pressure and particle monitoring can all be monitored in real time and recorded for an audit trail. Fully flush or semi flush LED display gives in-room feedback.

Download Data Sheet

GT Scan Max is our elite-level EMS – a 21CFR Part 11 compliant system combining state-of-the-art software and hardware to provide accurate readings for temperature, humidity, differential pressure and more.

GT Scan Pro is a flush-mounted multifunction pressure transmitter that can display up to three critical atmospheric parameters, utilising the reliable and highly sophisticated ONCALL-FINESTRA EMS system software.

Wall-mounted transmitter with user-friendly LED display in robust, attractive plastic housing. These multifunction sensors feature interchangeable probes and can display and measure parameters simultaneously.

Guardtech’s entry-level environmental monitoring system – a versatile analogue Magnehelic differential pressure gauge that indicates positive, negative or differential, accurate to within 1%.

This product range does not currently include a Fire Rated solution. Please consult a Guardtech rep for more information on your fire safety options.

2 Lighting

Powder-coated steel light units, flush mounted into the ceiling panels with drop-down hinged diffuser. Also available as surface-mounted aluminium LED batten luminaires for laboratories.

Activation by switch or PIR (passive infrared) sensor. Lights can be UV filtered for photo-sensitive processes.

Download Data Sheet

A top-end luminaire providing superior performance as well as optimum control via a Digital Addressable Lighting Interface (DALI) system. GT Lux Max is a recessed LED with a steel body, featuring SmartScan wireless tech, removing the need for control cabling.

GT Lux Pro is a high-quality and robust LED luminaire with a highly efficient light source – the unit opens from the top, meaning that maintenance is easy and decontamination risks are reduced.

GT Lux Plus is a highly efficient LED that has been engineered to be mounted in modular and suspended ceilings – the luminary body is made from steel sheet and powder coated in white.

GT Lux Lite is Guardtech’s entry-level light solution – an LED ceiling tile lighting panel that delivers on performance while allowing clients to save their budget for other critical areas of the project.

GT Lux Fire is Guardtech’s Fire Rated light solution – a high quality LED luminaire with a corrosion resistant, zinc-coated steel body that meets the requirements of Zone 1 hazardous areas.

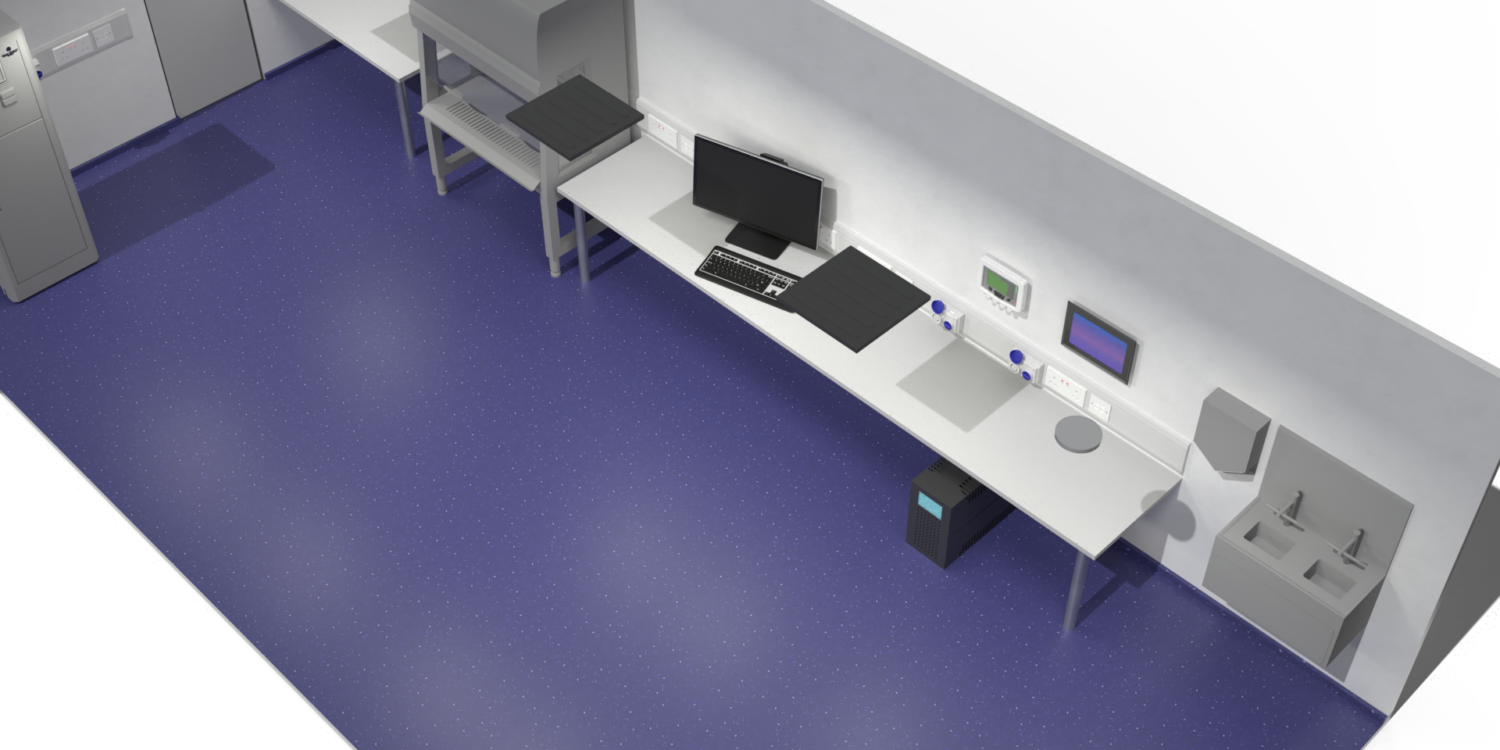

3 Building Management System

Full integration with client BMS or a separately commissioned Building Management System can be provided.

Typical integration includes HVAC, filtration, lighting, power management, extraction and any other utilities associated with the cleanroom. Typical software application provided by Trend.

4 Back-up Power

All cleanrooms require a power connection from an external source. The rating of this will depend on the power demand of each room.

UPS (uninterruptible power supply) battery back-up can also be provided and a changeover switch can be installed to alternate between a mains and generator supply.

5 Control Panel

Touchscreen HMI provides the interface for the controls and monitoring systems for your cleanroom. The EMS feeds back to give real-time data on temperature, humidity and pressure.

The BMS can link back data concerning the operational status of all plant, including fan speeds, coil condition, run data and other connected utilities.

6 Fire Alarm

In-room smoke detectors and audible and visual alarm beacons can be installed and linked back to a centralised fire alarm panel.

This can be connected back to the main facility fire panel board if required.

7 3-Phase Power

Often highly technical client process equipment requires a three-phase power supply, 16A, 32A or 63A outlets for this need to be factored in to the equipment layouts to establish best positioning and to accommodate concealed cable runs.

8 Small Power

Cleanroom Solutions are an NIC EIC accredited electrical contractor and conduct full electrical installations for all cleanroom plant, as well as providing power sockets for client equipment.

Containment can be implemented simply with cleanroom compatible antimicrobial three-compartment trunking or with smarter integrated solutions such as concealed service channels and flush sockets.

9 Network

CAT6, 6A or 6E data outlets flush mounted or installed within trunking, cabled back to network patch panel for client connection to host building server. Can also be incorporated into the EMS and BMS.

10 Containment

For cleanrooms, Guardtech install sockets and services flush to the panel system with containment embedded within the panel core.

For laboratories, three-compartment PVC trunking is used for flexibility of socket positioning and cost effectiveness.

11 Electrical Register

Determining electrical requirements of the cleanroom in conjunction with the diversified load of client process equipment is conducted at design stage via a detailed electrical register.

This will identify a total load assessment for comparison against the incoming building supply as well as outlining estimated heat load to be factored in to the HVAC design.