INDUSTRY-LEADING 3D SCAN TECHNOLOGY

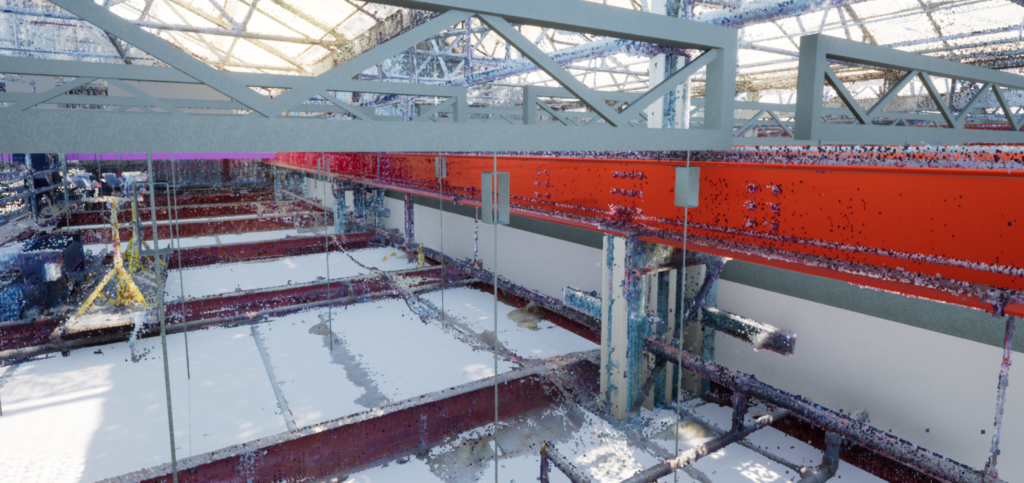

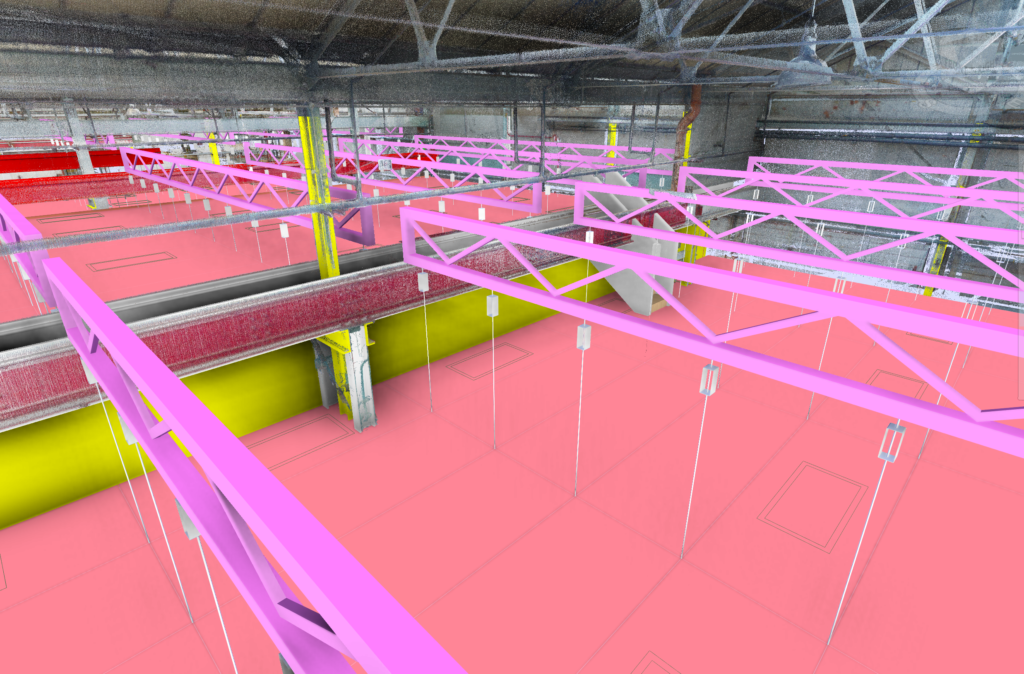

CLEANROOM SOLUTIONS have embraced the next level of design technology by incorporating 3D laser scanning into the beginning of their process as a detailed room information data capture.

Using cutting-edge technology from industry leaders Leica, a full 680,000-point-per-second scan with spherical images can be captured within 20 seconds, incorporating a maximum scan distance of 60 metres at an accuracy of 4mm tolerance.

Entire facilities can be transferred into an accurate 3D model from a site survey that can be completed in as little as one hour.

The information that this provides is invaluable to the design process and enables for full clash detection to be initiated whilst always considering the exact confines and restrictions of the host building.

This detailed scan identifies issues far earlier in the process, prior to manufacturing of components or attendance on-site. The benefits to the client are cost assurance and time-frame confidence, as challenges are encountered and overcome at the design stage rather than disrupting construction.

GUARDTECH GROUP CASE STUDY ISO7 AEROSPACE MANUFACTURING MODULAR

Discover the design innovation, processes and challenges behind an ISO7 Aerospace manufacturing modular cleanroom.

GUARDTECH GROUP CASE STUDY ISO7 MICROELECTRONICS FACILITY

Discover the design innovation, processes and challenges that went into this ISO7 Microelectronics Facility in Wales

Guardtech Group Make an Enquiry

Got a question for the Guardtech Group Commercial team? Click the button below to get rapid, direct access to Commercial Director Mark Wheeler, Commercial Manager Andrew Cressey, BDM Jack Pummell, Marketing Manager Joe Shackley and Nordics & Baltics Territory Manager Lars Strandljung.